Hydrim L110 G4: Advanced Instrument Reprocessing at MI Dental

Infection control is one of the most critical parts of dentistry. Traditionally, instruments were rinsed under tap water, then placed into an ultrasonic bath for cleaning. While effective for its time, this process involved multiple steps and frequent manual handling, leaving more room for variability.

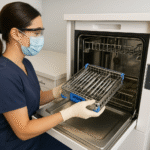

At MI Dental, we have advanced to the Hydrim L110 G4 instrument washer, a state-of-the-art system that provides consistent, validated cleaning and digital cycle tracking, ensuring both safety and efficiency for every patient.

How Hydrim Works

- High-pressure heated water jets rotate around instrument cassettes, attacking debris from every angle.

- Detergent dosing is precise for each cycle, ensuring consistent and repeatable results.

- Active drying system ensures instruments move directly to sterilization without manual handling.

This means that every cycle is controlled, repeatable, and documented — a major step forward from traditional ultrasonic cleaning.

Why Hydrim is Superior to Ultrasonics

- No manual scrubbing or pre-soaking required.

- Reduced risk of sharps injuries and contamination.

- Automated cycles deliver the same validated results every time.

- Capacity: up to 2,500 instruments thoroughly cleaned in a single 10-hour day.

Unlike ultrasonics, which depend heavily on operator consistency, Hydrim is designed to remove variability and produce the same validated standard across every load.

Infection Control in the COVID Era

The COVID-19 pandemic underscored the importance of stringent infection prevention and control (IPAC) in dentistry. Offices were inspected more closely than ever, and new standards for air management, surface disinfection, and sterilization documentation were introduced. At MI Dental, adopting the Hydrim system was not just about convenience — it was about future-proofing our sterilization center.

By automating cleaning and documentation, Hydrim ensures compliance with RCDSO and international standards (ISO 15883-1 & -2). Every cycle is logged, validated, and ready for inspection, giving our team complete confidence that nothing slips through the cracks.

Smart Technology Integration

Hydrim is not just a washer — it is connected.

- G4 Technology: WiFi or hardwired connection to our central sterilization computer.

- Cycle Monitoring: Each cycle records temperature, time, and parameters.

- Alerts: If a cycle fails to meet standards, it is immediately flagged and recorded.

- Touchscreen Display: Provides in-depth, real-time cycle information.

This digital record-keeping ensures full traceability, protecting both patient safety and staff accountability.

Benefits for Patients and Staff

- Instruments are thoroughly cleaned, dried, and ready for sterilization.

- Safer working environment for staff — less handling of contaminated sharps.

- Greater patient confidence in our infection control protocols.

- Reliable technology reduces downtime and eliminates guesswork.

- Staff can focus on clinical care instead of manual cleaning, improving efficiency across the practice.

Fun Fact

While Hydrim looks like a sleek “dishwasher,” it is far more advanced — engineered specifically for medical instruments and compliant with strict international standards for reprocessing.

Our Commitment

At MI Dental, Dentist Kitchener, we believe infection control should never be compromised. With Hydrim, our patients can rest assured that every instrument used in their care has been cleaned to the highest possible standard, documented digitally, and prepared with safety in mind.